Even ‘Mighty Ships’ need mighty weather routing

Weather routing is far more than the TomTom of the high seas. Plotting a course from A to B is not so hard. The hard thing is to develop an optimum track for any particular ocean voyage, based on weather forecasts, sea conditions, the ship’s individual characteristics and cargo; below- and on deck. Within specific limits of weather and sea conditions, the term optimum can mean maximum safety and crew comfort, as well as minimum fuel consumption, minimum time underway, ETA / Lay-can or any desired combination of these factors.

Benefits of weather routing with Optimum Ship Routing

Weather has a very significant effect on the shipping and offshore industry. Vessels encountering heavy weather will experience speed reduction due to increased resistance from wind and waves. In addition, heavy weather poses a safety risk to the crew, as well as to the ship itself from excessive ship motion, slamming or seas washing over the decks. When ships enter gale force or higher wind fields this strongly impacts the ability for the master to maneuver the vessel.

Optimum ship routing is the art and science of developing the “best route” for a ship based on the existing weather forecasts, ship characteristics, and cargo requirements. For most voyages this will mean the minimum transit time, and so least cost while avoiding significant risks to the vessel, crew and cargo. The goal is not to avoid all adverse weather but to find the best balance to minimize time of transit and fuel consumption without placing the vessel at risk to damage or crew injury. The savings in operational cost come about by reducing transit times, fuel consumption and cargo and hull damage as well as more efficient scheduling of dockside activities. Additional savings come from increasing the service life of the vessel and reduced insurance costs.

Environmental factors of importance to ship weather routing are those elements of the atmosphere and ocean that may produce a change in the status of a ship transit. In ship routing, special consideration is given to wind, seas, fog, ice, and ocean currents. While all of the environmental factors are important for route selection and surveillance, optimum routing is normally considered attained if the effects of wind and seas can be optimized.

Various studies have shown that optimum ship routing savings in time and fuel range from 2% to as much as 5% depending on the type of vessel, season and ocean. On average savings should run between 4-8%. Calculating with an average savings of 5% and a bunker price of about $500/ton, a ship burning 50 tons of fuel per day would see savings of over $8500 on fuel costs alone, during a 7 day transit, not to mention the savings in transit time.

Optimized Weather Routing with SPOS

Route-planning and optimization involves juggling safety, efficiency, navigation, costs, port rotation, ETAs, speed ranges and additional constraints, such as trim and seakeeping. For ship captains, this is a complex challenge that requires the aid of a decision-supporting tool to give them confidence in their decisions and support either and execution. DTN developed SPOS to address these challenges.

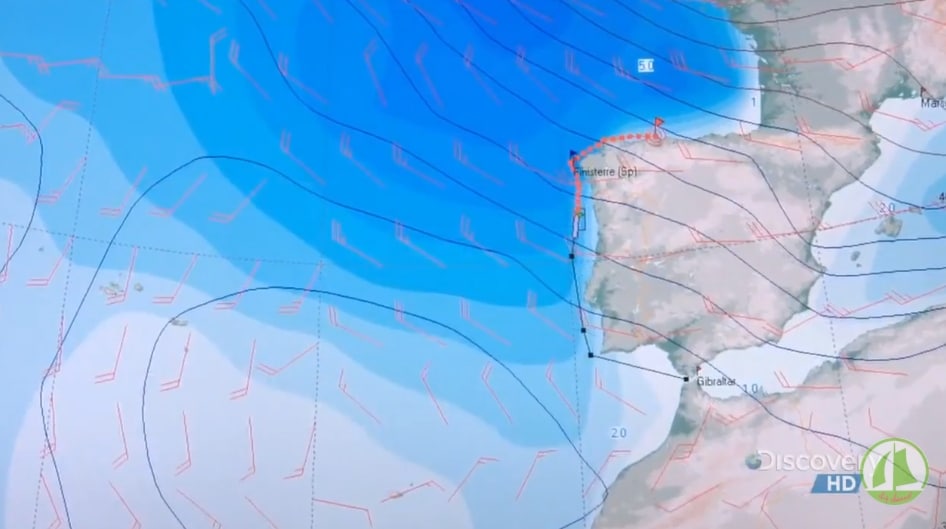

SPOS creates route options based on time, cost or fuel constraints, either with or without a given ETA. With the DTN Route network captains can plan port-to-port routes, including navigational constraints and port approaches. Variable speed routing functionality ensures ships can avoid severe weather.

Ships receive input up to four times a day, via e-mail or HTTP download. Weather maps can be displayed on a screen or printed. There are over 20 input parameters for voyage optimization, salinity for ballasting, humidity and dew point for cargo ventilation.

Ship and cargo characteristics have a significant influence on the application of ship weather routing. Ship size, speed capability, and type of cargo are important considerations in the route selection process prior to sailing and the surveillance procedure while underway. A ship’s characteristics identify its vulnerability to adverse conditions and its ability to avoid them.

Ship performance curves (speed curves) are used to estimate the ship’s Speed of Advance (SOA) while transiting the forecast sea states. The curves indicate the effect of head, beam, and following seas of various significant wave heights on the ship’s speed.

As each vessel has its own performance curves, which vary widely according to hull type, length, beam, shape, power, and tonnage. The DTN Ship Profile Library, developed with MARIN, contains advanced algorithms for the resistance impact of wind and waves on specific vessel types.

Mighty Ships need mighty weather routing

SPOS has been on the market for a while, and some of the biggest companies and fleets are now using this proven system. A beautiful example of how the SPOS system supports even the mightiest of ships, is found in an episode of Discovery Channel’s Mighty Ships series.

The episode follows Jumbo Shipping’s heavy lift cargo ship MV Fairplayer on her first mission, transporting supersized oil refinery equipment across the Mediterranean and the Atlantic. Fairplayer was built to be one of the world’s strongest muscle ships, able to lift and carry almost 14,000 tons. Transporting five enormous oil refinery components weighing in at 4,800 tons, in this episode, she is carrying some of the biggest, heaviest pieces any ship has ever hoisted. Featuring – in an important supporting role – the DTN SPOS system (‘Fairplayer’s sophisticated weather forecasting service’), notably on minutes 18:30, 21:20 and 38:00.

Jumbo is a heavy lift shipping and offshore transportation & installation contractor. Jumbo has been developing pioneering solutions for ocean transportation for more than 45 years. Since 2003, building on our heavy lift capability, Jumbo rapidly established a sound track record in the offshore subsea installation market.

Comprehensive weather insights help safeguard your operations and drive confident decisions to make everyday mining operations as safe and efficient as possible.

Comprehensive weather insights help safeguard your operations and drive confident decisions to make everyday mining operations as safe and efficient as possible. Learn how to optimize operations with credible weather and environmental intelligence. From aviation safety to environmental compliance, our comprehensive suite of solutions delivers real-time insights, advanced forecasting, and precise monitoring capabilities.

Learn how to optimize operations with credible weather and environmental intelligence. From aviation safety to environmental compliance, our comprehensive suite of solutions delivers real-time insights, advanced forecasting, and precise monitoring capabilities.